Description

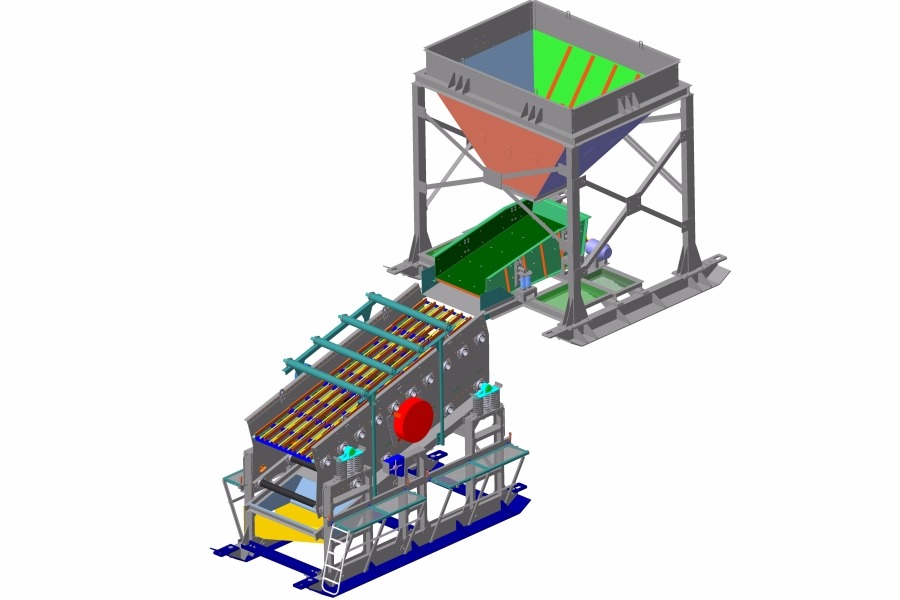

The wash plant consists of two separate units: a screening module and power module. Each module is equipped with an individual drive and can operate autonomously. Modules are installed cascade with respect to each other by frame. Versions of the ushing complex with a lock, sluice-jigging and jigging power enrichment system, with a complete set of various types of screens and pumps, according to the customer's request, are possible. The supply of screening material into the bunker of the power supply module is carried out by an excavator, loader or dump truck. Washing complexes can be manufactured on the basis of screens of the various capacities: GIT-42 MB, GIT-52 MB, GIT-62 MB, and also GIT-62ME.

JSC” Mining Machines” oers to expand the operational characteristics of the industrial device by power supply module upgrading. A large-capacity hopper of 22 m - has been specically designed to feed material directly from the dump truck body. This eliminates the need for an excavator or loader in the processing line.

The wash-sorting complex allows solving two problems:

- Wash a large amount of sand;

- Increase the extraction of gold from the legacy placers.

Completing units of machine:

- Loading hopper – loading with the help of an excavator or loader bulk material to the process line;

- Vibrating feeder – charging of sand from the hopper to the screen;

- Screen - separation of fractions.

- The irrigation system provides forced erosion of the sands on the washing ight of the screen with the ability to adjust the working pressure of the water supplied to the nozzles from 2 to 4 atmospheres, which makes it possible to wash eciently any type of sand.

- The lockage is equipped with a cavitator on the interface of the sludge line with the gateways.The cavitator creates the eect of cavitation, which ensures an even distribution of pulp on the sluices and extension of sand.

In the presence of large share of hard-to-recover gold, the PSK can be equipped with an additional trapping system with jigging machines of the MOD type.

- Jigging machines are equipped with grids of various sizes,

- depending on the grain size of the deposit sands;

- Jigging machines are equipped with a heavy bed. Experts choose the structure of the bed; adjust the amplitude and frequency of the jigging machines;

- Methods of ling in jigging machines: by gravity; hydraulic elevator.

Flushing and screening plants manufactured by UGMK Rudgormash-Voronezh LLC can be manufactured on the basis of the following screens:

Specifications

Technical characteristics of the unbalanced-throw screens of heavy-duty type GIT-52MM

|

Parameters |

GIT-52ММ |

|---|---|

|

Feeding lumps size, mm, not more |

60 |

|

Bulk density, t/m3, not more |

2,8 |

|

Feedstock output, t/h |

600 |

|

Screening surface type - Upper |

Ruber sieve contains of dialing-set |

|

Screening surface type - Lower |

Polyurethane sieve orplat rubber sieve |

|

Dimensions of screening surface, mm |

4 000 x 1 750 |

|

Active area of one sieve, m2 |

upepr 5,25 lower 7 |

|

Number of screening surfaces |

2 |

|

Screening angle, grad. |

15-30 |

|

Engine installed power, kW |

18,5 |

|

Frame vibration amplitude, min-1 |

3-8 |

|

Frame vibration frequency, min-1 |

730 |

|

Overall dimensions of screen vibrating part, mm, not more |

4 260 x 2 400 x 1 600 |

|

Mass, kg, without engine, cover |

5 217 |